Why Diamonds Are Used As Cutting Tools

Everyone knows how precious a diamond is and how commonly you see them for engagement rings. However, due to various factors, diamonds also have a very practical use: as a cutting tool. We have all heard of the way to test if a diamond is real by scratching it against glass. If the glass scratches, then the diamond is real. That is because it is very difficult to scratch a diamond and it is easy for a diamond to scratch other materials, like metals.

Diamonds are widely used in cutting tools, because they are considered to be the hardest element around. Able to cut through many different hard materials. Over the years, the use of diamonds has split into two main elements:

- jewelry production

- industrial-grade diamonds used on cutting tools

When a diamond is used in industrial tools, you do not need to look so closely at the 4 Cs of diamonds. Instead, all you need to care about are small pieces of diamond. These small particles of industrial-grade diamonds are perfect to embed in saw blades, grinding wheels, and drill bits. Diamonds are successfully used on the edges of saw machines, circular saw blades, and diamond saw blades. And in general, machines fitted with diamonds last longer than those with conventional saw blades. The diamond tool manufacturing industry utilizes diamonds for various purposes and instruments and we are happy to supply them.

About Industrial Diamonds for Diamond Tools Manufacturing

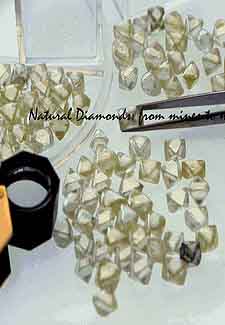

An industrial diamond is any diamond that is designated for industrial use, mostly as a cutting tool or as an abrasive. In general, industrial diamonds are too badly flawed, poorly colored, irregularly shaped, or too small to be of value as gems. However, they are very important in the modern metalworking and mining industries for the manufacturing of diamond tools. Their overall utility stems from the fact that diamond is the hardest natural substance known.

Industrial diamonds can be mined from natural deposits or they can be produced synthetically. There are three types of naturally occurring diamonds and they are: ballas, bort, and carbonado.

- Ballas, or also called a shot bort, is composed of concentrically arranged, spherical masses of minute diamond crystals. Ballas is extremely hard, tough, and difficult to cleave. Principal sources are Brazil and South Africa.

- Bort is a gray to black massive diamond. The color a bort is caused by inclusions and impurities. The name is also applied to badly colored, flawed, or irregularly shaped diamond crystals that are unsuited for gem purposes. 75% of the world’s crushing bort comes from Congo. The main use of bort is for the manufacturing of grinding wheels for sharpening cemented carbide metal-cutting tools.

- Carbonado is a black opaque diamond. It is as hard as crystallized diamond but generally less brittle. And due to its structure, it is slightly porous and has a lower specific gravity. Since carbonado has no cleavage, it is valuable for use in diamond-set tools and its manufacturing, such as rock coring drills. Other common applications include saws for cutting rocks and other hard materials, cutting tools, glass cutters, hardness testers and wire-drawing dies. This diamond usually occurs in small masses in the diamond-bearing gravels of Bahia, Brazil, and in Borneo.

USA Diamond Tool Manufacturing

If you are looking for a manufacturer of diamond tools in the USA, then you have come to the right place! Diamonds, due to their hardness, can be used to make manufacturing tools and are the perfect abrasive. Who knew, right? And sometimes you need a diamond to make a diamond. The cuts you get in those cases are unlike anything you’d get with other tools. Learn more about the uses for raw diamonds. And read on to learn more about diamond tool manufacturing and its advantages to businesses, such as the use of diamond drill bits.

More Information

- Diamonds Used as Abrasives

- About Diamond Drilling

- Uses for Raw Diamonds

- About Diamond Drill Bits

- Form Dressers Information

4 Advantages of Diamond Grinding Tools

As mentioned, different tools offer different benefits. Diamond grinding tools are some of the more popular tools you will find on the marketplace. You can use diamonds to make grinding tools. These tools present the user with some wonderful benefits. These benefits include:

- High Grinding Efficiency, Low Grinding Force: Less heat will be generated by the hole in the grinding process, which decreases or avoid burns and cracks on the surface of the workpiece. Ultimately decreasing the equipment’s wear and energy consumption.

- High Wear Resistance: The change in dimension with diamond grinding tools is small, which subsequently leads to good grinding quality and high grinding precision.

- Long Lifespan & Dressing Period: A longer lifespan of the product increases the work efficiency. It also improves the workers’ labor environment, while simultaneously decreasing the product’s labor intensity.

- Low Cost: The processing cost of each workpiece is lower for diamond grinding tools.

Applicable Materials

A diamond tool is typically suitable to process a variety of different materials, which makes their manufacturing process more important. Here are some of the more popular materials:

- Carbide alloy.

- Hard or abrasive non-metallic materials: stone, concrete, asphalt, glass, ceramics, & gemstones.

- Non-ferrous metals: aluminum, copper and their alloys.

- Some soft but tough materials: rubber and resin.

Grinding processes generates a high temperature for which the diamonds react with a variety of metals under. Typically, diamond tools are not able to process steels due to the high temperature needed. Tools made with common abrasives can do the job. At Lieber & Solow, we offer natural diamonds for advance precision applications. Use for a wide range of tasks. Get reliability you can trust!

What Are Diamond Form Tools?

Diamond form tools have diamonds lapped to specific angles and the correct radius needed for a particular application, machine, contour dressing system or CNC operation. There is a high degree of accuracy necessary and due to that fact the diamond is of special shape and quality.

How to Use Form Dressing Tools

- In order to minimize side pressure, proper centerline and light infeeds are crucial. Any excessive pressure will cause the diamond to fracture.

- Cone point tools should be rotated approximately 1/4 turn daily.

Cone Point Tools Features & Benefits

Cone point tools uses the Norton vacuum braze technology in the manufacturing, which surpasses all traditional diamond retention methods. Benefits of Norton vacuum braze technology include the following:

- absolute diamond retention.

- diamond pullout prevention during the dressing cycle.

- longer tool life through multiple relaps.

Since the diamond is accurately coned to the specific included angle and radius, these tools are ideal when the most intricate, precise forms and radii are required. Cone point tools can also be relapped for easier use.

U-Dex-It Cone Point Tool

The use of a U-Dex It cone point tool is for precision dressing of intricate forms and radii. They are specially designed with a 5/8″ indexable head for easy turning during use. These tools can be relapped.

Standard Cone Point Tool

The use of standard cone point tools are for precision dressing when the most intricate forms and radii are required. Can be relapped.

Industry Leader for Diamond Tool Manufacturing

The diamond tool manufacturing industry is vast, so it is important to have the exact tools you need for the job. When it comes to working with diamonds, different tools offer different benefits and applications. The selection of tools for diamond manufacturing includes dressing grinding wheels, drawing fine wire, precision cutting, drilling, construction, mining and exploration.

Lieber & Solow has years of experience working in the diamond tool manufacturing industry. We offer each and every customer a great selection of natural diamonds to choose from. On top of that, our customer service goes above and beyond for all of our clients. So please, do not hesitate to contact us today for more information.

We will gladly answer any questions or concerns you may have regarding our industry and products. You can also give us a call at your convenience. When you reach out, we can provide you with a helpful consultation to go over any questions you have about the diamond industry.