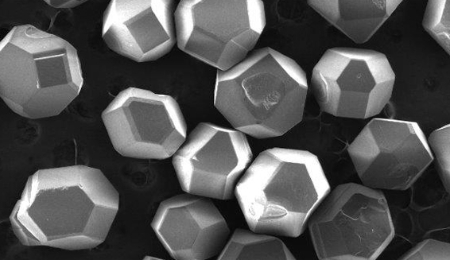

Diamond drilling is a cutting-edge drilling method that involves the use of diamond-impregnated drill bits. These drill bits are composed of industrial-grade diamonds that are especially designed to cut through hard materials like metal, concrete, and rock. A metal matrix called “the bond” is how the diamonds bond to the drill bit matrix. This combination of diamonds and bond enables the process of diamond drilling to achieve exceptional cutting efficiency and durability.

Diamond drilling has revolutionized various industries, including construction, mining, and exploration. It has the ability to penetrate and create precise holes in tough materials has made it an invaluable technique for a wide range of applications.

Basics of Diamond Drilling

To best understand diamond drilling, it is essential to understand the key components and principles involved with the process. The diamond drill bit is attached to a drilling rig, which provides the required power and stability for drilling operations. The drilling rig is a sophisticated piece of machinery, equipped with advanced features such as variable speed control and hydraulic systems to ensure precise and efficient drilling.

Water is used as a coolant and lubricant during the drilling process to reduce friction, prevent overheating, and carry away drilling debris. The water is delivered to the drilling area through a series of pipes and nozzles. These pipes and nozzles are strategically positioned in order to maximize cooling and cleaning efficiency. By continuously supplying water to the drilling area, diamond drilling eliminates the need for additional cleanup while also enhancing the efficiency of the drilling process.

Water is used as a coolant and lubricant during the drilling process to reduce friction, prevent overheating, and carry away drilling debris. The water is delivered to the drilling area through a series of pipes and nozzles. These pipes and nozzles are strategically positioned in order to maximize cooling and cleaning efficiency. By continuously supplying water to the drilling area, diamond drilling eliminates the need for additional cleanup while also enhancing the efficiency of the drilling process.

On top of all that, there is the ability to perform diamond drilling in various orientations, which includes vertical, horizontal, and inclined positions. This versatility allows operators to tackle drilling projects in challenging environments while also having access hard-to-reach areas with ease.

The Process of Diamond Drilling

The diamond drilling process begins with selecting the appropriate diamond drill bit. The selection of this bit is based on the material to be drilled and the desired hole size. The choice of drill bit is crucial. Its proper selection of different materials requires different types of diamond bits to achieve optimal cutting performance. The drilling rig is positioned, and the drill bit is aligned with the designated drilling location.

With the activation of the drilling rig, the diamond drill bit penetrates the material with its rotating motion. The downward force aids the process. The cutting action of the diamond-impregnated drill bit gradually creates a clean and precise hole. While using, the operator must carefully control the drilling parameters. These parameters include rotation speed and feed pressure. All of this ensures efficient drilling and prevents potential damage to the drill bit.

Throughout the drilling process, the operator carefully monitors the drilling parameters, which includes rotation speed, feed pressure, and water flow. These factors ensure optimal performance and maintain the integrity of the drill bit. Customize the drill hole to best meet your specific requirement, which may include depth, diameter, and angle. Diamond drilling offers numerous advantages over conventional drilling methods. Its precision and efficiency result in minimal material waste, as well as reduced environmental impact. On top of that, diamond drilling produces smooth and accurate holes. This process eliminates the need for further machining or finishing.

Contact Lieber & Solow

Ultimately, diamond drilling is an advanced and versatile drilling technique revolutionizing many different industries. Its ability to cut through hard materials with exceptional precision and efficiency makes it an indispensable tool for construction, mining, and exploration projects. With ongoing advancements in diamond drill bit technology and drilling rig design, the future of diamond drilling looks promising, promising even greater capabilities and applications. Contact us today to learn more about our efforts in this industry.

We have been operating in the diamond industry since 1927 with a headquarters in New York City. Over the decades, we have become some of the world’s leading suppliers of natural industrial diamonds. And we proudly supply a full line of materials to diamond tool manufacturers around the world. Get the best in rough natural diamonds when you turn to Lieber & Solow!